FOR US, TAKING RESPONSIBILITY MEANS PROTECTING THE THINGS WE LOVE!

When speaking about corporate responsibility, we use the term “sustainability“ with the utmost care. In everything we do, we leave traces in the environment in some way, shape or form. In powder snow, on trails - and certainly with every product we manufacture and sell.

We do not intend to embellish ourselves with words that make us appear “greener“, instead, we believe in honest and authentic transparency in our communication.

This implies explaining as precisely as possible what it means to produce our products and what challenges this process poses for the world we live in. And we also explain which steps and measures we are taking now and in future to reduce or even avoid completely the negative traces of the entire process.

This transformation cannot happen all at once, nor can it be implemented over night, however, it is a matter that is very close to our hearts. Here you can accompany us on every step of the way.

// MISSION

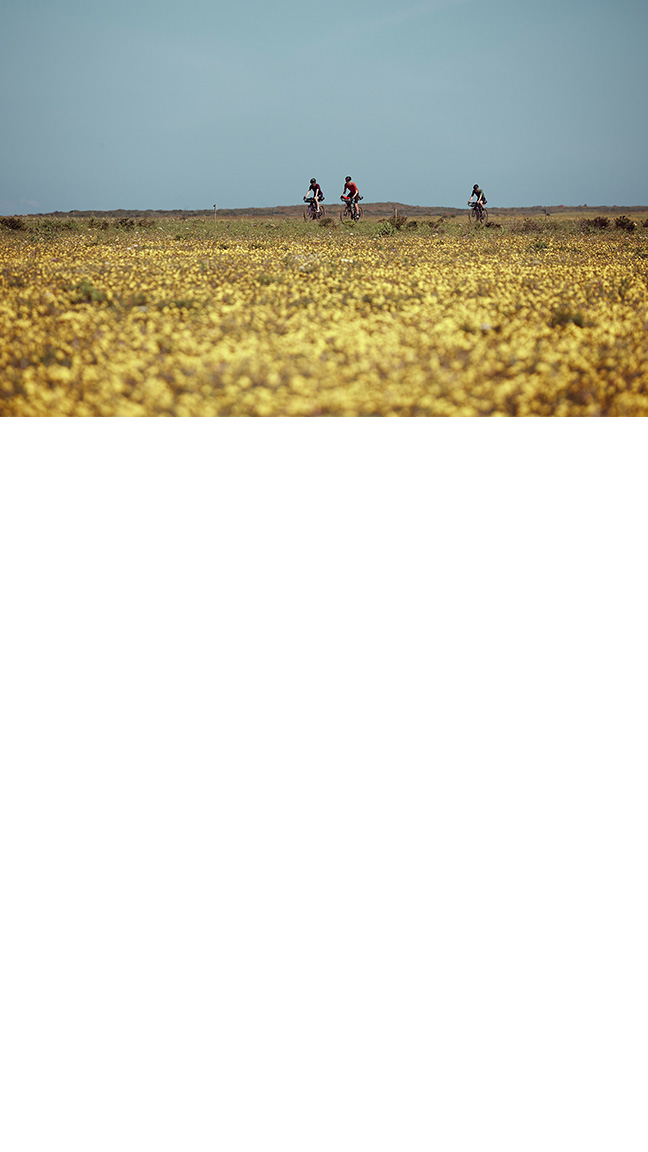

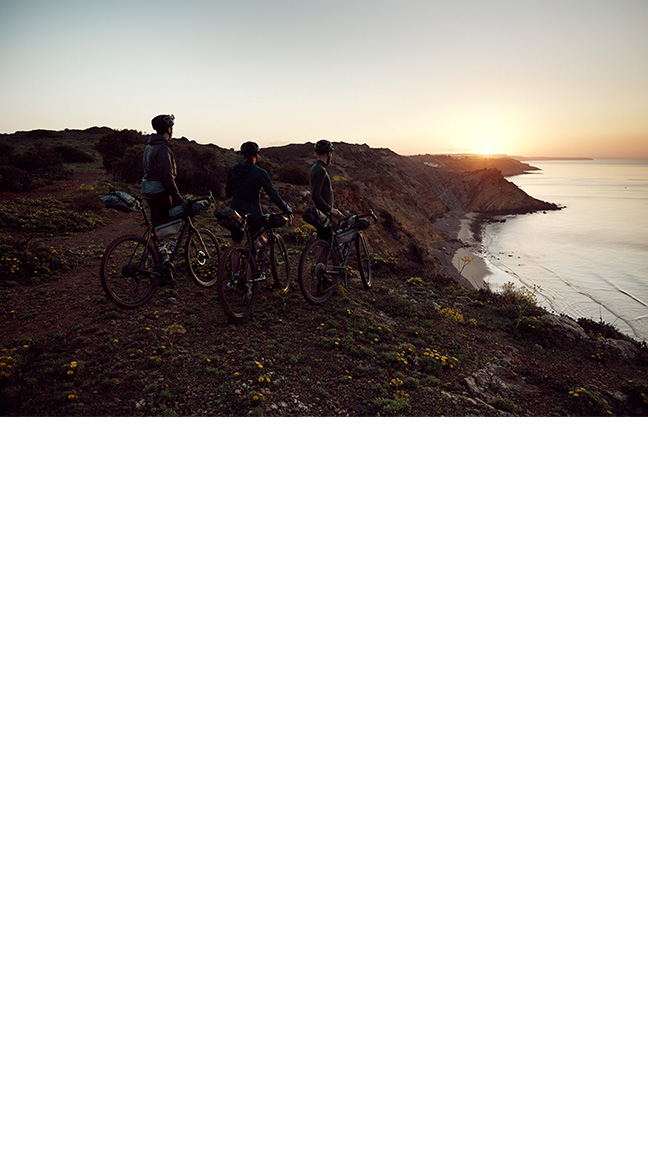

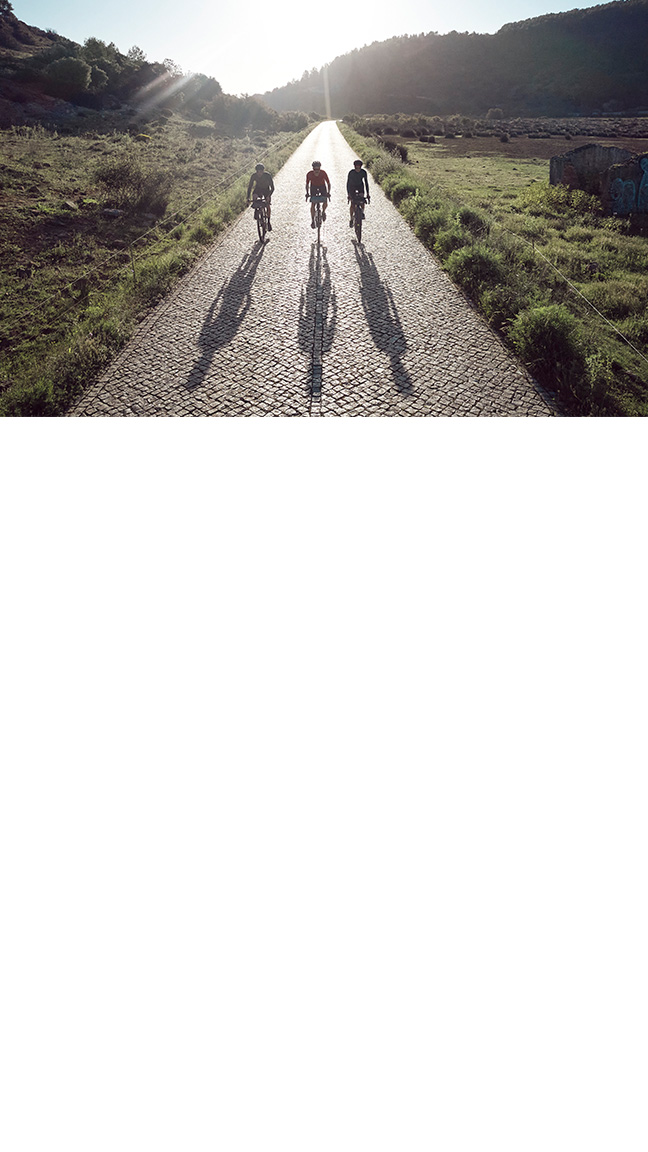

EVOC stands for evolution and the concept of high-quality, sports backpacks, bags, and luggage with a particular focus on proper protection of rider and gear. For us, sport and travel mean adventure, unique experiences, and a good time with friends. Our products are always a little more than just items of equipment.

For us, "Protect the things you love" not only means doing everything possible to protect you and your equipment, but also the nature in which we love roaming.

Our goal is to create a community within which all employees, partners, producers, and customers want to share this approach with us.

In doing so, we do not only focus on developing innovative products that conserve resources as much as possible.

We also take social responsibility, promote partnerships, live an open and honest communication, and are always striving to further improve our overall (ecological) impact on the world in our daily work.

// OUR GOALS

1. Goal

By 2025, EVOC will be 100 % climate neutral at its Munich site by reducing and offsetting all emissions.

EVOC is moving in the direction of climate-neutral business activities. The first step involves our Munich headquarters, business trips, and all forms of employee mobility. We are developing a plan to reduce our emissions based on the 2021 carbon footprint which we are compiling in cooperation with Climate Partner. Unavoidable emissions will be compensated for in the final step with a select climate protection project.

2. Goal

By 2030, we will have reduced all emissions in our global value chain by 50 % compared to 2022:

One of our priorities is to avoid and further reduce greenhouse gas emissions in all of our business operations. To achieve this, products will be optimized for resource-efficient production based on the 2021 carbon footprint of certain reference products. Furthermore, we will transition to more ecologically viable transport solutions along the supply chain. By choosing dedicated distribution partners and using targeted communication, we will actively influence the environmental awareness of our customers.

3. Goal

EVOC and all of our production partners will be certified (by 2025) according to certain social standards.

People are at the centre of our business activities, whether as employees, customers, business partners, or shareholders. We must ensure that all parties involved are treated fairly and protected in the best possible way. To this end, EVOC plans to get certified according to a particular social standard in order to be able to subsequently require certification of its production partners. EVOC is also actively involved in social projects.

4. Goal

By 2030, at least 80% of all EVOC products will have a recycled and/or organic-based material content of more than 50%.

EVOC constantly aims to make its products better, safer, and more enduring. Particular attention is paid to the use of lower-emission materials, especially those that are recycled, organic-based, and PFC-free. In product development, we always strive for the principle of material purity.

// PRODUCTION FACILITIES

MATERIALS

Unsere Produkte sollen die perfekten Begleiter deines Abenteuers zu allen Witterungsbedingungen sein. Dabei ist uns wichtig, dass sie zu 100% verlässlich performen, egal was passiert. Aus welchen Materialien der jeweilige Rucksack etc. besteht, bildet den Kernaspekt des jeweiligen Produktes.

Um Outdoor- und Sportequipment zu imprägnieren und somit Produkte weitgehend wasserabweisend zu gestalten, werden häufig per- und polyfluorierte Chemikalien, kurz PFC, verwendet. Hierbei handelt es sich um Kohlenstoff-Verbindungen, bei denen die Wasserstoff Atome durch Fluor ersetzt wurden. So werden Oberflächen wasser-, schmutz- oder fettabweisend - ein Faktor, der bei unseren Produkten wesentlicher Bestandteil der Entwicklung ist.

Allerdings sind diese Stoffe keine natürlich vorkommenden Stoffe. Sie sind demnach nicht oder nur sehr langsam auf natürlichem Weg abbaubar.

Aus diesem Grund haben wir es uns zum Ziel gemacht, eine umweltschonendere Alternative zur Imprägnierung zu finden. Dabei wollen wir jedoch in keinem Fall an Qualität oder Funktionalität einbüßen. Bei manchen unserer Produkte gestaltet sich das aus diesem Grund zwar etwas schwierig, jedoch haben wir bei Neuentwicklungen ein besonderes Augenmerk daraufgelegt, um dauerhaft Emissionen zu senken.

// PACKAGING

Switching to resource-saving alternatives not only plays a role in products, but also in the packaging thereof. Normally each product is packaged separately in order to save it from dirt and damage on the way from the production site to the consumer.

This adds up to a considerable amount of material. Simply omitting it is not really an option, because this would mean risking damage and that would not be viable either.

It is clear, however, that every reduction, every change towards resource-saving and more environmentally-friendly materials is enormously important.

In the following, we want to provide an overview of the steps we have taken up to this point, in order to reduce the environmental impact of our packaging and protective materials. These measures are by no means concluded, but are embedded in an ongoing process, the goal of which is to continuously check how we can become more ecologically compatible. Which elements can be omitted? Where can we reduce? Are there possibilities to re-use packaging? Are there recycled, recyclable, and more environment-friendly alternatives? New, more resource-saving technologies?

REDUCTION

Each of our products, for example, has to be provided with a label, a so-called hangtag. This is required so the product can be identified during transport and also at the retailers where it goes into the inventory systems. Aside from this product identification, it holds additional information for consumers. By providing more and more information online and making it accessible for consumers via QR codes on the hangtags, we can reduce their amount and volume.

RECYCLING

For our packaging and product labelling (displays, boxes, hangtags, …) we mainly use recycled kraft paper. We don’t employ plastic coating in order to help retain its recyclable properties.

RESOURCE SAVING

We have also reduced colour printing, and for the most part, we use environmentally friendly paint (e.g. soy-based) while all-in-all keeping the printed surfaces at a minimum. We have also reduced the various sizes of the packaging in general and by means of this optimization, we are able to save resources as well as streamline logistics.

On their way from the production sites to the dealers, our products are shipped in non-climatized containers. In order to save them from damage during the transport, they are supplied with little sachets for moisture regulation. Up to now, we have been using standard SILICA GEL sachets which we have then replaced with Micro-Pak Dri Clay® made with bentonite clay.

Why? Not only are they more effective, but they also have a higher eco-balance. There are no chemicals or water involved in their production and the energy required is minimal. What is more, it is packaged in FSC-certified kraft paper, biologically unproblematic and degradable.

THE CHALLENGE OF INDIVIDUAL PACKAGING

Our greatest challenge has been the redesign of the individual plastic Polybag packaging. We would just love to lose it altogether, however, it offers the best protection from damage and dirt during transport and storage. In the meantime, there are Polybags made of plant-based and bio-degradable plastic, but regrettably even though the name might suggest it, they cannot simply degrade in nature or normal compost.

Their decomposition requires conditions which only exist in industrial waste disposal sites. However, the infrastructure to ensure the plastic really gets to such facilities does not yet exist. Bio-degradable plastic that decomposes in the ocean is currently not durable enough to offer sufficient protection of the products during transport.

There is, however, another option which constitutes a significant improvement from an ecological standpoint. Individual product packaging made of paper. Wherever we can, we employ Glassine paper bags from VELA. They are transparent enough to identify the product within.

Made of FSC®-certified paper, it can be easily disposed of with other paper and hereby become a part of the recycling cycle. We are working hard on achieving a comprehensive changeover as soon as possible.

// TO BE CONTINUED...

We very much welcome your interest and are happy to see that the topic of environmental protection and corporate responsibility is important to you. Corporate responsibility, as well as the reduction of our environmental impact, is an ongoing process, which is why we will constantly update this page and add further information. Keep checking back from time to time or subscribe to our newsletter. And of course, we look forward to exchanging ideas with you.

Drop us a line at info@evocsports.com if you have any ideas or questions.

Your EVOC Team